Carrier Stall Error (IP60, LX600, LX610, LX910 or LX3000)

This error indicates that the printer is having trouble moving the cartridge carrier from side to side. Check the following:

1. Check for obstructions in the path of the cartridge carrier. Look for paper/media that has jammed or bubbled up and is blocking the path of the carrier. If you recently had a paper jam that you thought was clear, make sure you removed all the pieces of paper/media out of the printer.

2. Cartridge Cap Stuck. If the cartridge cap is not functioning properly it can cause this error. Please watch this video to ensure it is functioning properly. https://youtu.be/m_7H-ifaPmY

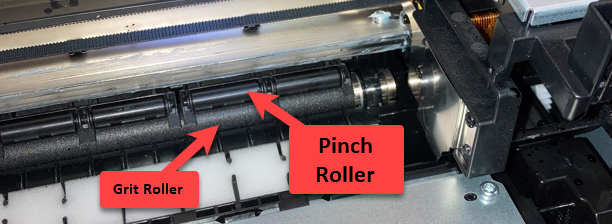

3. Check the pinch roller position to make sure it is pressed against the grit roller. You may be able to press this down and snap it back into place.

4. Check for a broken or missing encoder strip. The encoder strip is the semi-clear strip of plastic that spans the width of the printer's interior. The carrier reads the tiny printed lines on this strip to determine its position. If the carrier cannot read this strip because it is missing or out of place, it would cause this error. If the strip is broken or the hooks on either side are broken you may need to send the printer in for repair. However, it is also possible that the strip was knocked loose by a paper jam or even an operator's hand during a cartridge change. In this case, it can be reconnected to either side and the printer will function again. When you install the encoder strip, make sure it is not twisted. Also, make sure it is running flat behind the carrier in the proper reading slot position.

5. Update to the latest firmware. In some cases, the cross cutter mechanism can slip into the paper path and cause a wave in the media that transmits back to the print area, causing a bubble that the carrier contacts, causing the error. Go to PrintHub - Settings - Automatic Updates. The latest firmware will fix this problem.

6. Make sure the printer is resting on a stable surface that is not easily moved by the printer's printing motion. Excess table/bench/desk movement or wobble can cause carrier stalls.

7. Perforations. There is a natural weakness between the labels that is more pronounced by circle labels and perforated labels. This is where it starts to bubble. Avoid perforated labels if possible. They should not be necessary when using this printer since it has a cross cutter. (LX600/LX610 using die-cut labels only)

8. Any obstruction in the paper path can transmit a bubble back to the print area and cause a carrier stall error. First, check the star wheel plate. Remove two T10 torx screws holding it in place. Check the star wheels underneath to make sure they are seated properly and have some give when you push them. Also, check for burrs on the plastic piece. When reinstalling, make sure the plastic tabs fit into the slots on the platten. Second, check the cross cutter area for obstruction. Specifically check the orange clamp pad. This is visible if you are eye level with the media output area at the front of the printer. Make sure it is level all the way across and not higher in one particular area. If it is higher the adhesive may have failed which causes the pad to lift up and obstruct the print path.

Article ID: 031020

Related Articles

Arm Picker Error / Carrier Stall received on unit start up (Bravo 4100 Series, 4200 Series, SE, and SE-3)

This error typically indicates that the encoder strip is not being detected by the sensor on the back of the printer carriage. The encoder strip is the clear strip that spans the left to right distance where the printer carriage (cartridge holder) ...Carrier Stall Error (Eddie)

This error indicates the printer has trouble moving the cartridge carrier from side to side. Check the following: 1. Tighten the carrier belt tension. This article has a video of the process. 2. Check for obstructions in the path of the cartridge ...Cutter Stall Error (LX600-LX610)

The cutter referred to by this error message is the output cutter located at the front of the printer. This is a pizza wheel-style cutting disc that completely cuts through the label/media at the end of the job or at the end of every page, depending ...My LX610 or LX600 is skipping, slipping, printing over on the same spot or printing out of alignment left to right. Feed Stall. (LX610-LX600)

There are several reasons for skipping labels or a feed stall error on the LX-Series printers. A full article explaining all of the possibilities can be found here. See below for the LX600/LX610 specific reasons. Create Loop. Check the create loop ...How to fix an encoder strip that is out of place on your Primera Printer.

The encoder strip is a clear plastic strip with small timing marks printed on it, which tell the printer where the print head is located along the horizontal print head path. If it is knocked out of place due to cleaning, transport, or use, the ...