Vertical Target Error or Horizontal Target Error (FX1200)

1. The cutter sensor cannot find the eyemark/target. Manually adjust the web so that the target is in the carrier window.

2. The print quality of the target may not be sufficient. Check for light or inconsistent printing on the target.

3. The media may be feeding crooked. Check for any frayed edges. Adjust guides accordingly.

4. The target may have been printed too close or too far away from the edge of the media. Measure the distance from the edge of target to the front plate of the cutter. Go to Advanced Tab – Advanced Offsets – Horizontal Target Offset. Set the value to the measurement you took. Typically, you will need to increase this value by 0.1 or 0.2 inches. Default is 2.25.

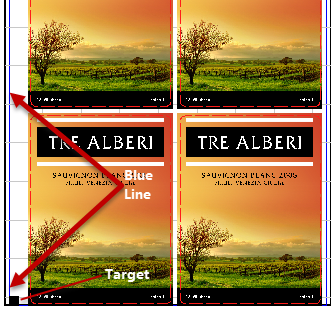

To fix this for future prints be sure to verify the position of the target in PTPrint before printing. It should be just to the right of the blue page guides (Blue Line) in PTPrint.

5. Check for laminate that is partially covering the target. It should be completely covering the target or not covering it at all. Partial coverage can cause a difference in the reflectivity of the target to the sensor. This will cause an error.

6. Ensure all three pinch rollers are engaged across the width of the material. You should not be able to move them from side to side when locked. Disengaged pinch rollers will cause the media to advance too far forward causing the target to move past the sensor. In addition to engaging all pinch rollers they need to be free of all toner dust and adhesive. Use rubbing alcohol and a lint free cloth to clean the pinch rollers. Goo-Gone or Goof Off! can be used to clean any adhesive residue.

7. Clean the sensor area with canned air. Cutter dust may have built up in the senosr area.

Article ID: 44656Related Articles

Top of Form (Vertical) Alignment: Gap Sensing Error. Label stock is not loading. Label alignment is printing vertically offset. There is a white line/gap at the top or bottom of my label. The image is printing too far down the label or too early (LX Series).

If labels are printing horizontally offset, try the solutions in this article: Labels are printing horizontally offset (left to right). The image is printing too far to the left or right. The LX series printer decides where to start printing by ...Error: "Image out of Bounds" when importing an image or printing. (LX610)

1. Reduce the imported image's DPI (dots per inch). PTCreate displays images at a set resolution of 150 DPI. If large DPI images are imported, they may exceed the display boundaries of PTCreate. Any image can be resized once imported. Primera ...Image Out of Bounds or Print Out of Bounds Error (Eddie)

This happens when your print image is moved beyond the printable area by adjusting horizontal and vertical offsets. Try these fixes. 1. Update Software and Firmware. Follow these instructions to update (Be sure to check the box for BETA updates) The ...What are the FX1200 cut file specifications including target mark size and position?

What are the FX1200 cut file specifications including target mark size and position? See the diagram below: Article ID: 44815The target mark is printing too close to the edge of the label stock (CX1200).

Problem: PTPrint displays target mark in correct position but the printer is printing the target mark too close to the edge of the label stock. Solution: Completely reinstall PTPrint following these instructions. Before uninstalling the current ...