The LX800 will not print the last few labels of my label stock.

The LX800 will not print the last few labels of my label stock.

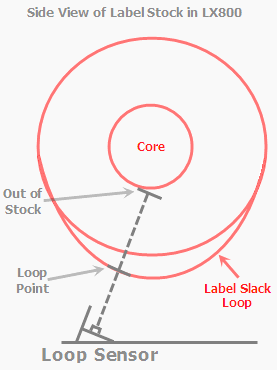

It is normal for the LX800 to not print the last several inches of labels. The out of stock sensor prevents the end of the label stock roll from being fed through the printer. If the stock did feed through the printer, this could jam the print mechanism since the label stock is attached to the core with tape. Below is an explanation of how the sensor works:

Inside the LX800 there is a Loop Sensor underneath the label stock roll. It performs two functions: First, it maintains a Slack Loop beneath the roll. This prevents the label feed device from pulling on taut label stock which can cause the labels to slip. Second, it senses when the label stock is out. If the Loop Sensor detects label stock higher than the Loop Point it unrolls the stock until the sensor sees the label stock at or below the Loop Point. The Loop Sensor will always tell the Roll Arm to unwind label stock when it sees the label stock higher than the Loop Point until it reaches the Out of Stock point. At this point the LX800 will produce an out of stock message.

If you would still like to print on the last several labels, try this procedure:

- Leave the labels fed through the front of the printer and simply unroll the remaining label stock and tear it off the stock core. Be sure to remove any tape from the last label.

- Drape the remaining label stock from the first roll out the back of the printer. You will need to leave the lid open to accomplish this.

- Load a new roll of label stock. Remove the tape from the first label. (IMPORTANT - DO NOT TRY TO FEED THIS THROUGH THE FRONT!) The labels from the first roll will lay over the top of the new roll.

Using this procedure, the loop sensor will detect a roll of label stock while your last labels from the previous roll will feed over top of this new roll and through the printer.

Note: If Out of Stock is consistently occurring earlier, perhaps with several feet of labels remaining instead of several inches, then the loop sensor may need to be calibrated by a service technician.

Related Articles

How do I correctly load the label stock to avoid feeding and printed image alignment offset problems? (LX Series)

Incorrect loading of the label stock is the number one reason for horizontally or vertically offset images and a variety of other feeding problems. Below is a top view of the printer with the cover open. There are several main areas to watch for when ...Primera's new Smart Part format for Custom Label Stock Explained

You can now see important information about your label stock embedded within the part number printed on a label inside the core. Read below for instructions on how to decipher this smart part number. SMART PART: The format is: PRI (for Primera) – ...How many labels per cartridge can I print? How can I calculate ink cost per label in Print Hub? (LX Series Printers)

The cost estimator is found under the queue section on the first tab of the Print Hub on PC and on the first tab of the Config Utility on Mac. On PC the last five job costs are stored in the list. Each job will show the cost per label based on the ...How do I create a label template in Bartender? (LX Series Printer)

When you open BarTender you will be given the choice to select an existing label or create a new one using a wizard. Use the following instructions as a guide through the wizard setup process. 1. Choose "Start a new BarTender document..." 2. ...How to Create A Custom Label Order

1. Go to https://www.primera.com/customlabel/generate/label/ 2. Select your printer type. 3. Then click Select Materials. View the material guide for more information on each material type of look at the pictures below. Premium Gloss Matte BOPP High ...