Magenta (Red) Ink is running or bleeding when printing with the Tuffcoat Extreme label stock. (LX400-LX810)

This article applies to the following stock:

-Tuffcoat Extreme Clear Gloss Polyester

-Tuffcoat Extreme White Gloss Polyester

-TuffCoat Extreme White Matte Polypropylene (BOPP)

To take advantage of the highly water-resistant features of this material, you must reduce the Ink Saturation setting in the LX Series Printer Driver.

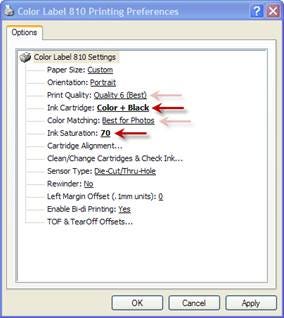

1a. PC Instructions: Go to Start – Control Panel – Printers and Faxes. Right click on the Color Label Printer icon. Select Printing Preferences.

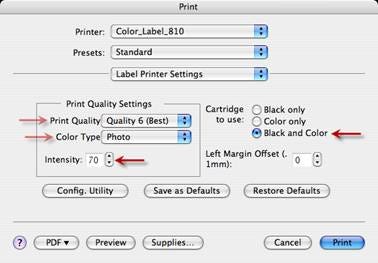

1b. Mac Instructions: Click Print from within any print application. Click the Copies and Pages drop down arrow. Choose Label Printer Settings.

2. Adjust Ink Saturation to 70% or lower. For graphics with large areas of black or black text against black background use Color + Black (LX810). Print Quality and Color Matching can also be adjusted to affect ink saturation.

3. Set the ink cartridge setting to Color + Black if possible (LX810). This helps with unnecessary over saturation of black areas when using all three colors in color only mode.

4. Please wait 24 hours before exposing the label stock to water. This gives the ink a chance to fully dry and set.

5. Use these settings as a guide. For some images, lower saturation will be required. For other images, higher saturation can be used. Images with large areas of magenta ink (LX810-LX400) next to an unprinted white background will most often require the lower saturation settings to prevent bleeding.

6. If possible, design your image to take advantage of the great features of the label stock and around the limitations. For example, given the limitations mentioned in item 5, it is recommended that you experiment with text colors that are set against a white background. Some colors may perform better than others.

Please note: Proper testing in the final application environment is recommended especially when used near water or chemicals. As with all pressure-sensitive materials, this product should be tested thoroughly under end-user conditions to ensure it will meet the requirements of the specific application.

If after following all of the suggestions above, you still have bleeding problems, it is possible that this material may not be suitable for your particular environment. Before returning the label stock, please contact tech support for other options or to determine if the stock may be defective. To determine if the stock is defective, tech support will require scans of printed label stock and your original artwork.

This article does NOT apply to the LX900. Labels printed on the LX900 will not bleed any colors.

Article ID: 44694Related Articles

How to Create A Custom Label Order

1. Go to https://www.primera.com/customlabel/generate/label/ 2. Select your printer type. 3. Then click Select Materials. View the material guide for more information on each material type of look at the pictures below. Premium Gloss Matte BOPP High ...How to print Red with Eddie Edible Ink Printer.

If your Eddie is printing red that looks more orange, use these tips to get the best possible red. White Frosting/Icing. The color of the printing surface makes a huge difference to the quality and color accuracy of the print. The "whiter" the white, ...How do I correctly load the label stock to avoid feeding and printed image alignment offset problems? (LX Series)

Incorrect loading of the label stock is the number one reason for horizontally or vertically offset images and a variety of other feeding problems. Below is a top view of the printer with the cover open. There are several main areas to watch for when ...Primera's new Smart Part format for Custom Label Stock Explained

You can now see important information about your label stock embedded within the part number printed on a label inside the core. Read below for instructions on how to decipher this smart part number. SMART PART: The format is: PRI (for Primera) – ...Ink on Labels are running, bleeding, scratching or smearing after water contact. (LX Series Printers)

In most cases, ink should not run or bleed from the label when exposed to water. However, certain images/label designs may be more susceptible to slight bleeding. Follow these steps to minimize bleeding. Use 53013 CMY + Ultra Black. If you are using ...