Labels are skipping, applying inconsistently or -SC- is displayed. (AP550).

Center the label Stock. The label stock must be centered in the feed space so that the gaps between labels intersect with the tick mark in the metal. The tick mark indicates the sensor position.

Black Mark(Reflective) or Die Cut Mode. Make sure you are in the correct Mode for your installed label stock. Clear labels must have a black mark on the back to be seen by the sensor. See Section 3.2.

Preprinted Labels. Labels with printing on the back of the liner may not work correctly since the sensor may mistakenly detect the printing on the back (or the front) of the label stock as a gap between labels. You may be able to adjust the position of the labels left or right in the feed area so the sensor avoids the printing.

A sensor calibration may be necessary. The Label Sensor must be calibrated to the specific label stock being used for each memory location. Use the following procedure to calibrate the applicator for your specific label stock/liner material or you may watch this AP550 Calibration Video.

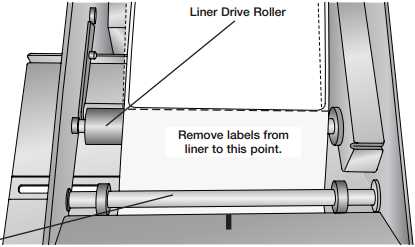

1. Load the label stock as described in Section 2 of the manual. The label stock must be centered in the feed space so that the gaps between labels intersect with the tick mark in the metal. Be sure to remove labels from the liner back to the Liner Drive Roller. For reflective stock, the black mark should be positioned directly under the Label Guide Roller. The goal is to feed only clean liner through the sensor area. This will give the sensor a good reading of the liner material.

2. Once the liner is loaded, follow the steps above to navigate to the SC- setting in the Setup Mode.

3. Lower the arm to trigger the calibration.

4. The label stock will move forward until the first label is presented for application.

5. Calibration for this liner is now complete and the values are stored in the current memory location.

Note: It is not necessary to recalibrate the label sensor between rolls of the same label stock.

Article ID: 44547

Related Articles

Will my clear labels with clear liner work with the AP360/AP362 or the AP550?

AP360 - AP362 uses a physical flag sensor to detect gaps between labels. The AP360/362 will work with Clear labels with a clear PET liner in most cases as long as the liner and the label are not too thin and the adhesive isn't too strong. The danger ...My LX610 or LX600 is skipping, slipping, printing over on the same spot or printing out of alignment left to right. Feed Stall. (LX610-LX600)

There are several reasons for skipping labels or a feed stall error on the LX-Series printers. A full article explaining all of the possibilities can be found here. See below for the LX600/LX610 specific reasons. Create Loop. Check the create loop ...My labels have bubbles or wrinkles. How can I resolve this? AP360/AP362/AP380

This issue can be caused by one of the following: 1. The container is not completely round, not smooth or has bumps or ridges. See this article on tapered containers. 2. The labels are applied crooked due to incorrect setup. See this article. 3. The ...PL400 is not applying labels or labels are gradually shifting vertically on the pouch (PL400).

The front pouch sensor flag spring is out of place or detached. If it is detached the PL400 will not apply any labels. If out of place or has lost its spring tension, it may gradually shift the label placement on the pouch. 1. Disconnect power from ...Recommended Spacing for Print and Cut File on LX610

Space Between Pages. The smallest space between pages on the LX610 when performing digital die cuts is 0.4". This distance will automatically be added by the printer between pages and will happen regardless if there is only one image on the page or ...