How long does the die cutting blade/knife and wear strip last? (LX610)

Digital Die-Cutting Blade Life

The longevity of the blades depends on

- the type of material being used;

- how much material was cut; and

- the number of times the blades scored through the liner coming into contact with the wear strip.

Blades can last up to 40,000 linear feet. However, in most cases, you will get less than that because of the factors above. Keep in mind that paper stock tends to wear down the blades at a faster rate than polyester or vinyl stock.

If your blades are suddenly not cutting, one or more may have broken. Look at the blades under low magnification (10x Loupe). You will be able to see the break. Breaks can occur if the blade comes in contact with and cuts through the wear strip. See the examples below. Purchase replacements here. Replace the blade using the instructions in the manual section 2E.

When to Replace the Cutter Wear Strip

The wear strip is the surface directly underneath the cutting blade in the cutter mechanism. Over

time, this strip will wear down due to cutter knife pressure. It can also be damaged if the knife cuts

through the liner and contacts the wear strip.

Replace the wear strip whenever you cut through the liner and create a groove in the wear strip plastic.

Replace the wear strip whenever you cut through the liner and create a groove in the wear strip plastic. o replace the wear strip, remove any media from the cutter mechanism. Power off the Printer.

Push the knife carrier gently to the left. Grab one end of the wear strip and pull it off the cutter. Use a utility knife to get under the strip if necessary. The wear strip is held in place with

adhesive, so there may be adhesive residue. Clean off the adhesive with isopropyl alcohol.

Remove the liner from the new wear strip. Press the strip into place. Make sure it is fully seated in

the recessed pocket. You may have trouble feeding the label stock into the printer if it's not fully seated.

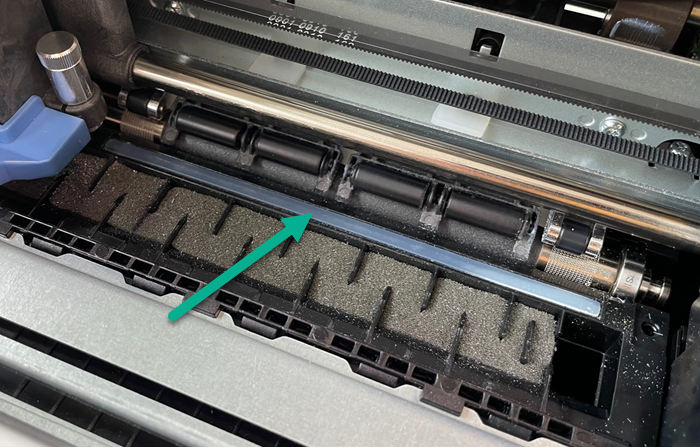

Example of a Wear Strip that needs replacement.

Instructions: Replacing the Wear Strip

Article ID: 120122

Related Articles

The LX610 goes through the motions of cutting out my label but nothing is cut.

1. Make sure you have the cutting knife installed. 2. Make sure the cutting knife holder is inserted all the way into the knife collar. 3. Make sure the blue collar release lever is pushed in. 4. The digital die-cutting blade may need replacement. ...How long do die cutting blades last? (FX1200)

How long do die cutting blades last? (FX1200) The longevity of the blades depends on the type of material being used; how much material was cut; and the number of times the blades scored through the liner coming into contact with the wear ...New Liner/Top Surface for Digital Die Cutting Stock listed below. (LX610)

Notice: Our old manufacturer, Avery, no longer makes the previous liner/backing paper or high gloss paper label stock, so unfortunately, we were forced to change to a new material. We tried our best to offer a similar material, but some differences ...The FX1200 is cutting rough, jagged lines and/or chattering as it cuts.

1. Replace the cutting knife. A dull or broken blade can cause rough cuts. 2. Replace the knife holder cap. The cap contains ball bearings that allow the blade to rotate as it moves around corners. If the knife fails to rotate after a turn the ...How do I cut the Magnetic Material for my LX610.

The recommended starting knife pressure for the magnetic media is 22. This media is not meant to be cut all the way through because there is no liner. Instead, this knife pressure setting is meant to score the magnetic media so that it can be removed ...